In the intricate dance of food preparation, there exists a hidden ally that often goes unnoticed—the humble chemical sprayer. As a food worker meticulously blends ingredients and crafts culinary masterpieces, the art of safely handling these potent solutions becomes paramount. Imagine a world where every spritz and spray is not just a culinary flourish, but a carefully calculated step towards maintaining hygiene and safety standards. Welcome to the realm where potency meets precision, where the judicious use of a *chemical sprayer* transforms a simple task into a symphony of sanitation.

In this comprehensive guide tailored specifically for food workers, we delve into the nuanced realm of *chemical sprayer* usage, uncovering the secrets to harnessing its power effectively and safely. From understanding the intricacies of dilution ratios to mastering the art of proper application, this blog post serves as your beacon of knowledge in the labyrinth of food safety protocols. So, as you embark on this enlightening journey through the mist of sanitization, prepare to elevate your craft and embrace the transformative potential of a well-handled *chemical sprayer*.

Understanding the Importance of Chemical Sprayer Safety

The importance of chemical sprayer safety cannot be overstated when it comes to maintaining food safety standards. In the fast-paced world of food preparation, where time is of the essence, it is crucial for food workers to understand the potential risks associated with handling chemical sprayers and take necessary precautions to ensure their own safety and that of others. Chemical sprayers are commonly used in the food industry for a variety of purposes, including cleaning and sanitizing surfaces, applying pesticides or herbicides, and even flavoring foods. However, if not used properly, these sprayers can pose serious health hazards. It is therefore essential for food workers to be well-versed in the different types of chemical sprayers used in their industry and understand how to handle them safely.

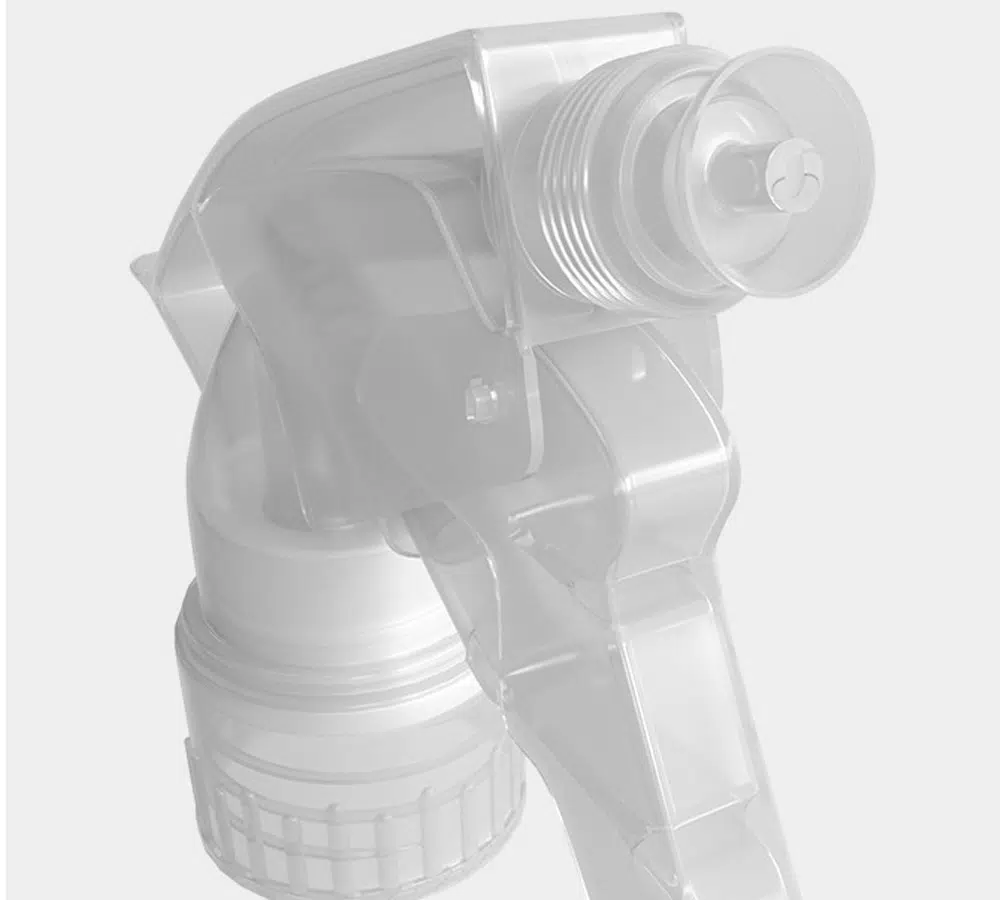

Types of Chemical Sprayers Used in the Food Industry

There are several types of chemical sprayers commonly used in the food industry. These include low-pressure sprayers, spot sprayers, and telescoping spot sprayers. Each type has its own unique features and applications. Low-pressure sprayers are typically used for general cleaning purposes. They operate at a lower pressure than other types of sprayers, making them ideal for delicate surfaces or areas where high pressure could cause damage. Spot sprayers are designed for the targeted application of chemicals. They have a narrow spray pattern that allows for precise spraying on specific areas or objects. Telescoping spot sprayers are similar to spot sprayers but come with an extendable wand that allows users to reach higher or hard-to-reach areas easily.

Essential Safety Precautions for Handling Chemical Sprayers

When it comes to handling chemical sprayers safely, there are several key precautions that food workers should always keep in mind. Read and follow instructions: Before using any chemical sprayer, carefully read the manufacturer’s instructions and follow them diligently. This includes understanding proper operating procedures, maintenance requirements, and safety precautions.2. Wear appropriate personal protective equipment (PPE): Personal protective equipment, such as gloves, goggles, and masks, should be worn at all times when handling chemical sprayers. This helps protect against potential exposure to harmful chemicals.3. Ensure proper ventilation: When using chemical sprayers indoors, make sure the area is well-ventilated to prevent the buildup of fumes or vapors. Open windows or use exhaust fans if necessary.4. Avoid direct contact with chemicals: Never come into direct contact with the chemicals being sprayed. This includes avoiding inhalation of fumes or mist and preventing skin or eye contact.

Proper Dilution Ratios for Different Cleaning Solutions

One of the critical aspects of using chemical sprayers effectively is understanding the proper dilution ratios for different cleaning solutions. Dilution ratios determine the concentration of the solution being sprayed and can vary depending on the specific cleaning task at hand. It is essential to follow manufacturer guidelines when diluting cleaning solutions to ensure optimal effectiveness without causing damage to surfaces or compromising food safety. Using too little solution may result in inadequate cleaning while using too much can lead to residue buildup or potential health risks.

Best Practices for Storing and Handling Chemicals

Proper storage and handling of chemicals are vital for maintaining their effectiveness and preventing accidents or contamination. Here are some best practices to follow. Store chemicals in a designated area: Keep all chemicals in a secure location away from food preparation areas, preferably in a locked cabinet or storage room specifically designated for chemical storage.2. Label containers correctly: Clearly label all containers with the name of the chemical, its concentration, and any necessary hazard warnings. This helps prevent accidental misuse or confusion.3. Separate incompatible chemicals: Some chemicals can react dangerously when mixed together. Store incompatible chemicals separately to avoid potential reactions that could release toxic gases or cause explosions.

Personal Protective Equipment (PPE) for Chemical Sprayer Use

When using chemical sprayers, wearing appropriate personal protective equipment (PPE) is crucial for ensuring the safety of food workers. The type of PPE required may vary depending on the specific chemicals being used and the potential hazards associated with them. At a minimum, food workers should wear gloves, goggles or a face shield, and a respirator mask when handling chemical sprayers. Gloves protect the skin from direct contact with chemicals, goggles or face shields shield the eyes from splashes or fumes, and respirator masks prevent inhalation of harmful vapors or particles.

Effective Techniques for Applying Cleaning Solutions

Proper application techniques are essential for maximizing the effectiveness of cleaning solutions while minimizing waste or potential hazards. Here are some effective techniques to consider. Maintain an appropriate spraying distance: Follow manufacturer guidelines regarding the recommended spraying distance for different cleaning solutions. This ensures optimal coverage without oversaturating surfaces.2. Apply in a controlled manner: Use smooth and even strokes when spraying to ensure consistent coverage. Avoid excessive spraying that can lead to runoff or unnecessary waste.3. Pay attention to target areas: Focus on areas that require thorough cleaning or sanitization, such as high-touch surfaces or hard-to-reach corners. Ensure adequate contact time for the cleaning solution to work effectively.

Common Mistakes to Avoid When Using Chemical Sprayers

While understanding proper usage is crucial, it is equally important to be aware of common mistakes that food workers should avoid when using chemical sprayers:1. Neglecting safety precautions: Failing to wear appropriate PPE or disregarding safety guidelines can result in serious injuries or health risks.2. Improper dilution ratios: Using incorrect dilution ratios can lead to ineffective cleaning or potential damage to surfaces.3. Overusing chemicals: Excessive use of chemicals not only wastes resources but also increases the risk of residue buildup and potential health hazards.

Testing and Maintenance of Chemical Sprayers

Regular testing and maintenance of chemical sprayers are essential for ensuring their proper functioning and longevity. Food workers should perform routine checks, such as inspecting hoses and nozzles for damage, testing pressure levels, and cleaning or replacing filters as needed.

Conclusion: Elevating Food Safety Standards with Proper Chemical Sprayer Use

In conclusion, the safe and effective use of chemical sprayers is crucial for maintaining food safety standards in the food industry. By understanding the importance of chemical sprayer safety, familiarizing themselves with different types of sprayers, following essential safety precautions, and adopting best practices for handling chemicals, food workers can contribute to a safer working environment. Proper dilution ratios, the use of personal protective equipment (PPE), effective application techniques, and avoiding common mistakes are all key factors in maximizing efficiency and minimizing potential risks associated with chemical sprayer use. By embracing these guidelines and investing time in testing and maintaining chemical sprayers regularly, food workers can elevate their craft by ensuring optimal cleanliness and hygiene in their workspaces. Together, we can create a safer environment where every spray is a step toward culinary excellence while upholding the highest standards of food safety.