In the innovative realm of plastic cap manufacturing, where precision meets creativity, Betterchois Company emerges as a cosmetic packaging industry frontrunner, orchestrating the intricate dance of turning raw materials into everyday essentials. Step inside their production facilities, and you’ll witness a symphony of machinery and expertise seamlessly converging to craft the unsung heroes of cosmetic containers. From concept to completion, each plastic cap embodies a meticulous process that not only ensures functionality but also exudes quality beyond measure. Embark on a journey through the inner workings of plastic cap manufacturers as we unveil the fascinating behind-the-scenes operations at Betterchois Company. Through a lens of ingenuity and dedication, this blog post peels back the layers of mystery shrouding the creation of these essential components, shedding light on the craftsmanship and technology propelling the industry forward. Join us as we delve into the heart of plastic cap production, exploring the seamless fusion of artistry and engineering that defines the very essence of Betterchois Company’s manufacturing prowess.

Raw Material Selection and Quality Control

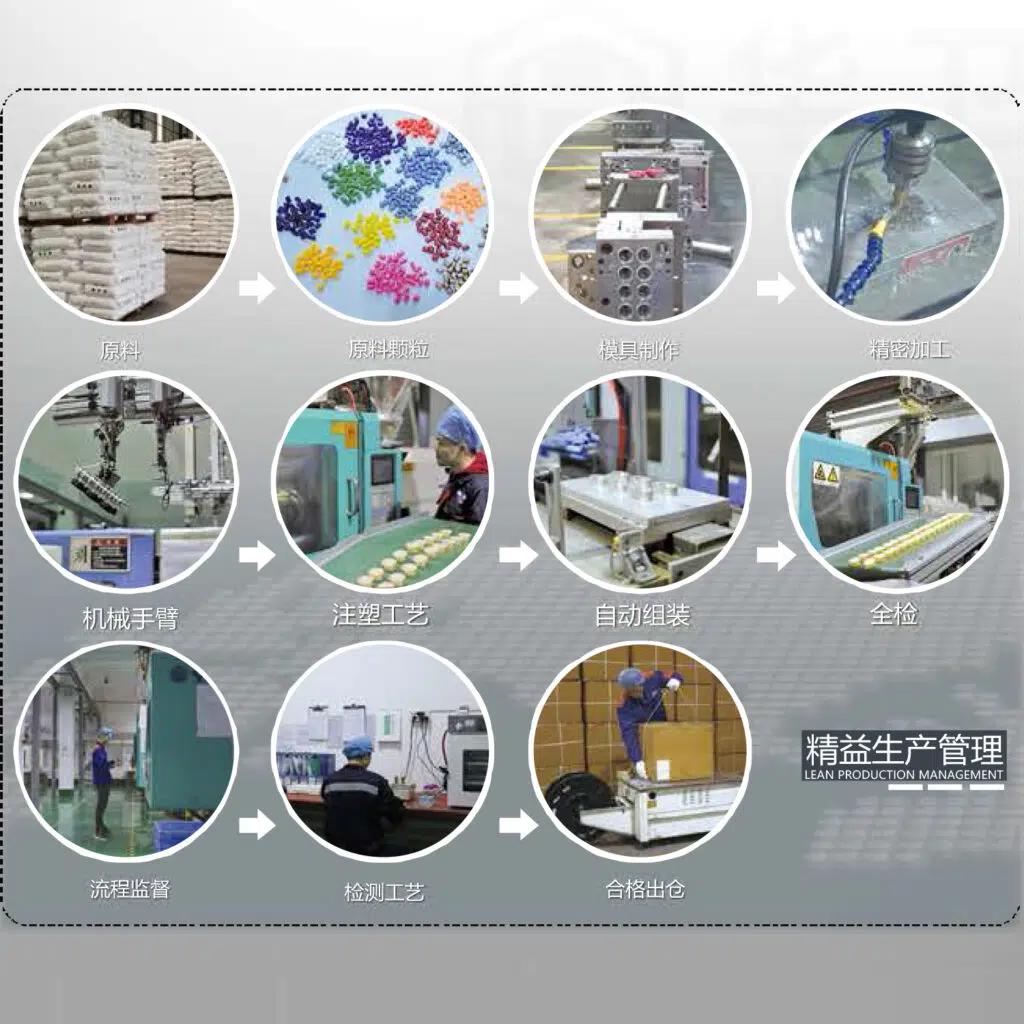

At Betterchois Company, the journey of plastic cap production begins with a meticulous process of raw material selection and quality control. The company understands the importance of using high-quality materials to ensure the durability and functionality of their products. They carefully source materials that meet strict industry standards, such as FDA-approved plastics, to guarantee safety for both consumers and the environment.

Before any production can commence, rigorous quality control measures are implemented to assess the integrity of the raw materials. This includes thorough inspections for any defects or impurities that may compromise the final product’s performance. By adhering to stringent quality control protocols, Betterchois Company maintains its reputation as a trusted manufacturer in the industry.

Design and Prototyping Process

The design and prototyping process at Betterchois Company is a harmonious blend of creativity and technical expertise. Their team of skilled designers works closely with clients to bring their visions to life while ensuring functionality and practicality. Using advanced computer-aided design (CAD) software, they create detailed 3D models that serve as blueprints for production.

Once the design is finalized, prototyping takes center stage. Betterchois Company utilizes cutting-edge technologies like 3D printing to produce physical prototypes for testing and evaluation. This iterative process allows for adjustments and improvements before mass production begins.

Injection Molding Techniques

The backbone of plastic cap manufacturing lies in injection molding techniques employed by Betterchois Company. This highly efficient method involves injecting molten plastic into a mold cavity under high pressure, resulting in precise replication of intricate designs.

Betterchois Company utilizes state-of-the-art injection molding machines equipped with advanced controls for temperature, pressure, and cycle time optimization. This ensures consistent quality across each production run. The company also embraces automation to streamline the process, minimizing human error and maximizing efficiency.

Sustainable Practices in Manufacturing

As a responsible plastic cap manufacturer, Betterchois Company is committed to sustainable practices throughout their manufacturing process. They actively seek eco-friendly alternatives for raw materials, such as biodegradable plastics or recycled materials, to reduce their environmental impact.

Additionally, Betterchois Company implements energy-efficient technologies and waste management systems to minimize resource consumption and reduce carbon emissions. By embracing sustainability, they not only contribute to a greener future but also cater to the growing demand for environmentally conscious products.

Customization and Personalization Options

Betterchois Company understands the importance of customization and personalization in today’s market. They offer a wide range of options for customers to tailor their plastic caps according to specific requirements. This includes various colors, finishes, textures, and branding opportunities.

Their team of experts works closely with clients to understand their unique needs and translate them into custom designs. Whether it’s embossing logos or incorporating intricate patterns, Betterchois Company ensures that each plastic cap reflects the brand identity of its customers.

Plastic Flip Top Caps

One of the popular types of plastic caps manufactured by Betterchois Company is the flip-top cap. These caps are widely used in cosmetic packaging due to their convenience and ease of use. The flip-top mechanism allows for one-handed operation while ensuring secure closure.

Betterchois Company offers a diverse range of flip-top caps in different sizes and designs to cater to various product requirements. From small vials to larger bottles, their flip-top caps provide reliable protection against leakage or spillage.

Plastic Disc Top Caps

Another type of plastic cap produced by Betterchois Company is the disc top cap. These caps feature a disc-shaped top that can be pressed down to dispense a variety of products, such as shampoo, body lotion, cleaning products, and other highly viscous personal care items. They are commonly used in personal care and household products. Simply push the cap indent found on top of the cap and the orifice is exposed. Once dispensing is complete simply push the orifice down to protect contents and prevent spilling. The sleek, flat top finish on our discs ensures a contemporary and durable dispensing closure.

Betterchois Company’s disc top caps are designed for precise product dispensing, allowing users to control the amount of product they need. The caps are engineered to prevent clogging or leakage, ensuring a smooth and mess-free experience for consumers.

There are lots of plastic disc top caps you can get here, with different neck finishes, different orifices, and different surfaces, such as smooth, ribbed, double-wall, 18/410, 20/410, 24/410, 28/410….Contact us to get more cosmetic packaging caps for Matching Your Bottles.

Plastic Spout Caps

Plastic spout caps manufactured by Betterchois Company offer a practical solution for products that require controlled pouring or dispensing. These caps feature a small spout that allows for precise application, making them ideal for liquids such as ketchup, oil, honey, or condiments.

Betterchois Company’s plastic spout caps are designed with user convenience in mind. The spouts can be easily opened and closed, preventing any accidental spills or wastage. Their precise engineering ensures a consistent flow rate, providing an optimal user experience.

Supply Chain Management and Logistics

A well-managed supply chain is crucial for the success of any manufacturing company, and Betterchois Company is no exception. They have established robust supply chain management systems to ensure timely delivery of their plastic caps to clients worldwide.

Betterchois Company collaborates with trusted suppliers who share their commitment to quality and sustainability. By maintaining strong relationships with suppliers, they can secure a steady supply of raw materials while adhering to ethical sourcing practices.

Quality Assurance and Testing Procedures

Quality assurance is at the core of Betterchois Company’s manufacturing process. They have implemented comprehensive testing procedures at every stage to ensure that each plastic cap meets the highest standards of quality and performance.

From material testing to functional assessments, Betterchois Company conducts rigorous quality checks to identify any potential issues or defects. This includes tests for durability, leakage, and compatibility with various products. By adhering to strict quality control measures, they deliver plastic caps that surpass customer expectations.

Betterchois Company’s Commitment to Excellence

At Betterchois Company, excellence is not just a goal; it’s a way of life. They are dedicated to continuous improvement and innovation in plastic cap manufacturing. Their team of experts constantly explores new technologies and techniques to stay ahead of industry trends.

By fostering a culture of creativity and collaboration, Betterchois Company encourages its employees to push boundaries and challenge conventional norms. This commitment to excellence is reflected in every plastic cap they produce, ensuring customer satisfaction and loyalty.

Need A Sample Or Quote?

If you’re interested in exploring the capabilities of Betterchois Company as a plastic cap manufacturer, they offer samples and quotes upon request. Simply reach out to their friendly customer service team, who will be more than happy to assist you with your inquiries.