Step into any beauty products, and you’ll be greeted by a dazzling array of products, each one vying for your attention. But it’s not just the optionable colors or enticing labels that draw you in; the very design of the packaging plays an equally crucial role. Among the latest innovations setting the beauty products abuzz is the disc top cap—a small yet revolutionary component that’s poised to redefine how we interact with our favorite cosmetics. Crafted meticulously with consumer convenience and sustainability in mind, these caps are emerging as game-changers in the realm of PP cap design. What makes them stand out? How are they shaping the future of cosmetic packaging?

As we delve deeper into this blog post, you’ll discover how the futuristic approach in PP cap design is not just about aesthetic appeal but also about functionality and environmental responsibility. The disc top cap offers a seamless user experience, allowing consumers to dispense just the right amount of product with a simple press. Gone are the days of fumbling with screw tops or dealing with messy spills. Moreover, made predominantly from polypropylene (PP), these caps bring to the fore a renewed focus on sustainable materials, reinforcing the industry’s move towards eco-friendly solutions. Get ready to explore how this seemingly modest component is making waves, setting new standards, and heralding a brighter, greener future in cosmetic packaging.

The Understanding of Cosmetic Packaging

Cosmetic packaging is not just about protecting the product; it is an essential element in creating a positive consumer experience. The packaging design plays a crucial role in attracting customers and conveying the brand’s message. With the ever-evolving beauty industry, manufacturers are constantly seeking innovative ways to enhance packaging functionality and aesthetics. One such innovation that has gained significant attention is the disc top cap.

Disc top caps are small, round-shaped components that sit on top of cosmetic bottles or tubes. They are designed to provide a convenient and controlled dispensing mechanism for various beauty products such as lotions, creams, shampoos, and more. These caps feature a disc-shaped opening that can be pressed down to release the desired amount of product.

Evolution Disc Top Caps in PP Cap Design

The evolution of disc top caps in PP cap design has revolutionized cosmetic packaging. Polypropylene (PP) is a popular material choice for manufacturing these caps due to its durability, flexibility, and chemical resistance. The use of PP ensures that the caps can withstand frequent usage without compromising their functionality or integrity.

Over time, manufacturers have refined the design of disc top caps to enhance their performance and user-friendliness. The caps now come with improved sealing mechanisms to prevent leakage or accidental spills during transportation or storage. Additionally, advancements in molding technology have allowed for intricate detailing on the cap’s surface, enabling brands to incorporate their logos or unique designs.

Advantages of Disc Top Caps in Cosmetic Packing

The adoption of disc top caps offers several advantages for both consumers and cosmetic brands:

- User Convenience: Disc top caps provide an effortless dispensing experience with their easy-to-use press-down mechanism. Consumers can precisely control the amount of product they want, reducing wastage and ensuring a mess-free application.

- Hygiene: The disc top caps help maintain the hygiene of the product by preventing direct contact with fingers or other contaminants. This feature is particularly crucial for products that require a higher level of sanitation, such as skincare items.

- Product Preservation: The tight seal provided by disc top caps prevents air exposure, keeping the product fresh and extending its shelf life. This is especially beneficial for formulations that are sensitive to oxidation or contamination.

Sustainability and Environmental Impact of PP Cap Design

In recent years, sustainability has become a key focus in the beauty industry. Consumers are increasingly demanding eco-friendly packaging solutions that minimize environmental impact. Disc top caps made from PP address this concern by offering a sustainable alternative to traditional packaging materials.

PP is a recyclable material, meaning that disc top caps can be easily recycled and repurposed into new products. By choosing PP cap design, cosmetic brands contribute to reducing plastic waste and promoting a circular economy. Furthermore, the lightweight nature of PP helps reduce carbon emissions during transportation, making it an environmentally responsible choice.

Innovative Features of Disc Top Caps

The continuous innovation in disc top cap design has led to the incorporation of various features that enhance their functionality and appeal:

- Child-Resistant Closures: Some disc top caps come with child-resistant closures to ensure product safety in households with young children.

- Tamper-Evident Seals: Tamper-evident seals provide consumers with peace of mind by indicating if the product has been tampered with before purchase.

- Customizable Designs: Brands can customize the appearance of disc top caps to align with their brand identity, creating a unique and recognizable packaging solution.

Design Versatility and Customization Options

Disc top caps offer design versatility and customization options that allow cosmetic brands to stand out in a competitive market. Manufacturers can produce caps in various colors, finishes, and sizes to cater to different product lines or target demographics. The ability to create visually appealing packaging helps attract consumers’ attention and build brand loyalty.

Moreover, disc top caps can be paired with different bottle or tube materials, such as glass or plastic, depending on the desired aesthetic and functionality. This flexibility enables brands to create cohesive packaging solutions that align with their overall brand image.

Market Trends and Consumer Preferences

The beauty industry is constantly evolving, driven by changing consumer preferences and market trends. Disc top caps have gained popularity due to their user-friendly design and sustainable attributes. Consumers appreciate the convenience offered by these caps, as they provide a hassle-free application experience.

In addition, the growing awareness of environmental issues has led consumers to seek out products packaged in sustainable materials. Disc top caps made from PP meet this demand by offering an eco-friendly alternative without compromising on functionality or aesthetics.

Challenges and Limitations in Adopting Disc Top Caps

While disc top caps offer numerous benefits, there are some challenges associated with their adoption:

- Caps Compatibility: Disc top caps may not be compatible with all types of bottles or tubes due to variations in neck sizes or threading mechanisms. Brands need to ensure proper compatibility during the packaging design phase.

- Packaging Costs: Implementing disc top caps may involve additional costs compared to traditional packaging options. However, the long-term benefits, such as improved user experience and sustainability, often outweigh the initial investment.

Case Studies: Success Stories in Implementing Disc Top Caps

Several cosmetic brands have successfully implemented disc top caps in their packaging solutions, achieving positive results:

Brand A: Brand A introduced disc top caps for their range of body lotions. The user-friendly design received positive feedback from consumers, leading to increased sales and brand loyalty.

Brand B: Brand B incorporated disc top caps in their shampoo bottles. The precise dispensing mechanism reduced product wastage and spillage, resulting in cost savings and improved customer satisfaction.

The Role of Disc Top Caps in Shaping Cosmetic Packaging

The future of cosmetic packaging lies in innovative solutions that prioritize user convenience and sustainability. Disc top caps represent a significant step forward in PP cap design, offering a seamless dispensing experience while minimizing environmental impact.

As more cosmetic brands recognize the benefits of disc top caps, we can expect to see an increase in their adoption across various product categories. With continuous advancements and customization options, these caps will continue to shape the way we interact with our favorite beauty products.

In conclusion, disc top caps are revolutionizing cosmetic packaging by combining functionality, sustainability, and aesthetic appeal. Their convenient dispensing mechanism, coupled with the use of recyclable materials like PP, makes them an ideal choice for brands looking to enhance consumer experience while reducing their environmental footprint. As the beauty industry moves towards more eco-friendly practices, disc top caps are poised to play a crucial role in shaping the future of cosmetic packaging.

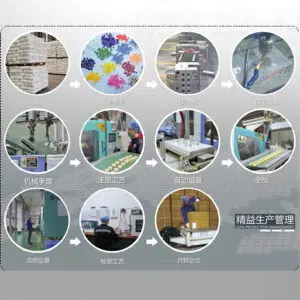

Betterchois offer different sizes polyproylene caps, various bottle caps, they can also customize different plastic caps according to the customers’ requirements. They have more than 100 sets injection machines, their daily output for screw caps of cosmetic packaigng products are over 2 millions pieces.