In the beauty world of consumer goods, where packaging plays a crucial role in ensuring product safety and market appeal, one company stands out as a paragon of quality and innovation: Betterchois. Located in Shantou China, this trailblazing HDPE bottle manufacturer has redefined industry standards by combining cutting-edge technology with unparalleled craftsmanship. From pharmaceutical containers to everyday household personal care products, Betterchois bottles are the silent guardians of purity and integrity, safeguarding contents while presenting them in an aesthetically pleasing manner.

But what sets Betterchois apart in the competitive landscape of bottle manufacturing? It’s a story of relentless pursuit of excellence, rooted in a deep understanding of client needs and market trends. This blog post journeys into the heart of Betterchois’ operations, revealing how they have managed to earn their status as the leading manufacturer in China. We will explore their state-of-the-art facilities, innovative processes, and the rigorous quality control measures that ensure each bottle meets the highest standards. Prepare to uncover the secrets behind Betterchois’ success and learn why they are the go-to choice for companies seeking reliable HDPE bottle solutions.

Innovations in HDPE Bottle Manufacturing at Betterchois

At Betterchois, innovation is at the core of their HDPE bottle manufacturing process. They constantly strive to push the boundaries of what is possible, utilizing the latest technologies and techniques to create bottles that are not only functional but also visually appealing. With a team of skilled engineers and designers, Betterchois is able to bring their clients’ visions to life.

One of the key innovations at Betterchois is their use of advanced 3D printing technology. This allows them to create prototypes quickly and accurately, enabling clients to see and feel the final product before it goes into production. By using 3D printing, Betterchois can also make adjustments and improvements to the design without incurring significant costs or delays.

In addition to 3D printing, Betterchois has also invested in state-of-the-art blow molding machines. These machines allow for precise control over the shape and size of each bottle, ensuring consistency across production batches. The use of such cutting-edge technology not only improves efficiency but also reduces waste, making Betterchois a leader in sustainable manufacturing practices.

Cutting-Edge Technology Utilized by Betterchois

Betterchois understands that staying ahead in the industry requires constant innovation and investment in new technologies. That’s why they have embraced cutting-edge technologies such as injection molding and extrusion blow molding.

Injection molding is a process where molten plastic is injected into a mold under high pressure. This allows for the creation of complex shapes with high precision and repeatability. At Betterchois, they have advanced injection molding machines that can produce HDPE bottles with intricate designs and features.

Extrusion blow molding, on the other hand, involves melting plastic resin and then blowing it into a mold to create the desired shape. This process is ideal for producing bottles with uniform wall thickness and excellent clarity. Betterchois has invested in top-of-the-line extrusion blow molding machines, ensuring that their bottles meet the highest quality standards.

Unparalleled Craftsmanship: The Hallmark of Betterchois Bottles

While technology plays a crucial role in HDPE bottle manufacturing, craftsmanship is equally important at Betterchois. Their team of skilled artisans takes pride in their work, paying attention to every detail to ensure that each bottle meets the highest standards of quality and aesthetics.

From the selection of raw materials to the final finishing touches, every step of the manufacturing process is executed with precision and care. Betterchois understands that their bottles are not just containers but also reflections of their clients’ brands. That’s why they go above and beyond to create bottles that are not only functional but also visually appealing.

Whether it’s a sleek pharmaceutical container or an eye-catching personal care product bottle, Betterchois combines technical expertise with artistic flair to deliver products that stand out on store shelves.

Diverse Applications of Betterchois Bottles in the Cosmetic Personal Care Industry

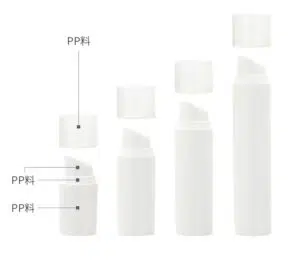

Betterchois’ HDPE bottles find applications across a wide range of industries within cosmetic personal care products. Their versatility and durability make them suitable for various products, including cosmetics, pharmaceuticals, household cleaning agents, personal care products, and more.

In the cosmetics industry, Betterchois’ bottles are used for packaging skincare products such as lotions, creams, and serums. The high-quality materials used in their manufacturing ensure that these products remain safe and protected from external contaminants.

In the pharmaceutical industry, Betterchois’ bottles play a critical role in preserving medication efficacy. Their airtight seals and robust construction ensure that the contents remain intact and unaffected by external factors such as moisture or light.

Furthermore, Betterchois’ bottles are also widely used in the household cleaning industry. The durability of HDPE makes it an ideal choice for packaging cleaning agents, ensuring that they can withstand the rigors of everyday use without compromising product integrity.

Quality Control Measures Ensuring Purity and Integrity of Betterchois Bottles

When it comes to manufacturing HDPE bottles, quality control is of utmost importance at Betterchois. They have implemented stringent measures to ensure that each bottle meets the highest standards of purity and integrity.

One such measure is their rigorous testing process. Each batch of bottles undergoes thorough inspections to check for any defects or imperfections. This includes visual inspections, leak tests, and measurements to ensure dimensional accuracy.

Betterchois also places a strong emphasis on traceability. They maintain detailed records for each production run, allowing them to track and trace every bottle back to its source. This not only ensures accountability but also provides valuable data for continuous improvement.

In addition to testing and traceability, Betterchois follows strict hygiene practices throughout their manufacturing facilities. This includes regular cleaning and sanitization procedures to prevent contamination and maintain a clean production environment.

Sustainable Practices Embedded in Betterchois’ Manufacturing Processes

Betterchois is committed to sustainability and has integrated eco-friendly practices into its manufacturing processes. They understand the importance of reducing their environmental footprint while still delivering high-quality products.

One way they achieve this is through the use of recycled materials. By incorporating recycled HDPE into their bottle production, Betterchois helps reduce waste and conserve natural resources. They work closely with suppliers who share their commitment to sustainability, ensuring a reliable source of recycled materials.

Furthermore, Betterchois has implemented energy-efficient technologies in its manufacturing facilities. They have invested in energy-saving equipment and optimized their production processes to minimize energy consumption. This not only reduces their carbon footprint but also lowers operational costs.

Additionally, Betterchois actively promotes recycling among its customers and end-users. They provide information on proper recycling practices and encourage the use of recyclable materials in packaging design. By raising awareness and advocating for sustainable practices, Betterchois aims to create a more environmentally conscious consumer goods industry.

Client-Centric Approach: How Betterchois Understands and Meets Customer Needs

At Betterchois, customer satisfaction is at the forefront of everything they do. They take a client-centric approach, striving to understand and meet the unique needs of each customer.

One way they achieve this is through close collaboration with clients during the design process. Betterchois works closely with its customers to understand its beauty brand identity, target market, and product requirements. This collaborative approach ensures that the final bottle design aligns with the client’s vision while also meeting functional requirements.

Betterchois also offers customization options to cater to specific client needs. From color matching to logo embossing, they can tailor each bottle to reflect the client’s brand identity. This level of customization helps companies differentiate themselves in a competitive market.

In addition to customization, Betterchois provides excellent customer support throughout the entire manufacturing process. Their dedicated account managers are available to address any concerns or questions that clients may have, ensuring a smooth and seamless experience from start to finish.

Market Trends Analysis and Adaptation Strategies at Betterchois

Betterchois understands that staying ahead of market trends is crucial for success in the bottle manufacturing industry. They continuously analyze market trends and consumer preferences to identify emerging opportunities and adapt their strategies accordingly.

By keeping a close eye on market trends, Betterchois can anticipate the needs of its clients and proactively develop innovative solutions. This allows them to stay one step ahead of the competition and offer products that are in line with current market demands.

Furthermore, Betterchois actively seeks feedback from its clients and end-users. They value input from their customers and use it to drive product improvements and innovation. By listening to the voice of the customer, Betterchois ensures that their bottles not only meet industry standards but also exceed customer expectations.

Global Reach and Impact: Betterchois’ Presence in the International Market

Betterchois has established a strong presence in the international market, exporting its HDPE bottles to customers around the world. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation as a trusted supplier in the global consumer goods industry.

With a focus on continuous improvement, Betterchois is constantly expanding its reach and exploring new markets. They actively participate in international trade shows and exhibitions to showcase their products and connect with potential customers.

Betterchois’ international success can be attributed to its ability to adapt to different market requirements. They understand that each region may have unique preferences or regulations when it comes to packaging. By tailoring their products to meet these specific needs, they have been able to establish long-lasting partnerships with clients worldwide.

Betterchois’ Leading Position in HDPE Bottle Manufacturing

As a result of their unwavering commitment to quality, innovation, and customer satisfaction, Betterchois has emerged as the leading HDPE bottle manufacturer in China today. Their state-of-the-art facilities, cutting-edge technology, unparalleled craftsmanship, and sustainable practices have set them apart from the competition.

Companies seeking reliable HDPE bottle solutions turn to Betterchois for their expertise and track record of delivering exceptional products. With a focus on continuous improvement and a client-centric approach, Betterchois is poised to maintain its leading position in the industry for years to come.

When it comes to HDPE bottle manufacturing in China, Betterchois is the name that stands above the rest. Their commitment to quality, innovation, and customer satisfaction sets them apart from the competition. Whether it’s pharmaceutical containers or everyday household personal care products, Betterchois bottles are trusted by companies around the world. With cutting-edge technology, unparalleled craftsmanship, and a client-centric approach, they continue to redefine industry standards and solidify their position as the go-to choice for reliable HDPE bottle solutions.